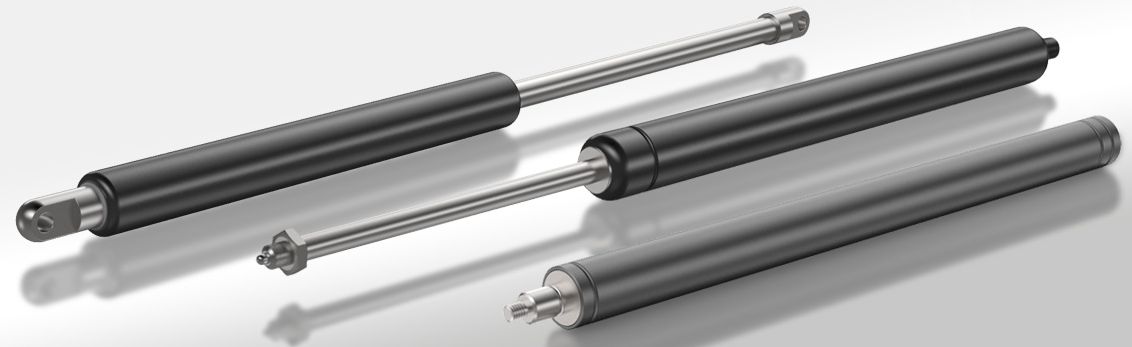

Gas springs

Gas springs are extremely versatile components that are used in a wide range of industries. The large selection of different sizes and strengths and the simple attachment enable a very wide range of applications and functions. Wherever masses need to be moved, lifted or held in a controlled manner and with a controlled amount of force, gas springs are the component of choice.

The materials used for the cylinder, piston, seals and end fittings of gas springs can vary. The choice of suitable material depends on various factors, including requirements for strength, durability, corrosion resistance, temperature resistance and weight limitations.

Gas spring

Gas springs can facilitate or control the movement of an element, e.g. a door, by maintaining a constant force.

Product range

Rigid locking gas springs

Rigid locking gas springs can block the movement of a component and hold it in a fixed position. This is achieved by a special holding mechanism.

Product range

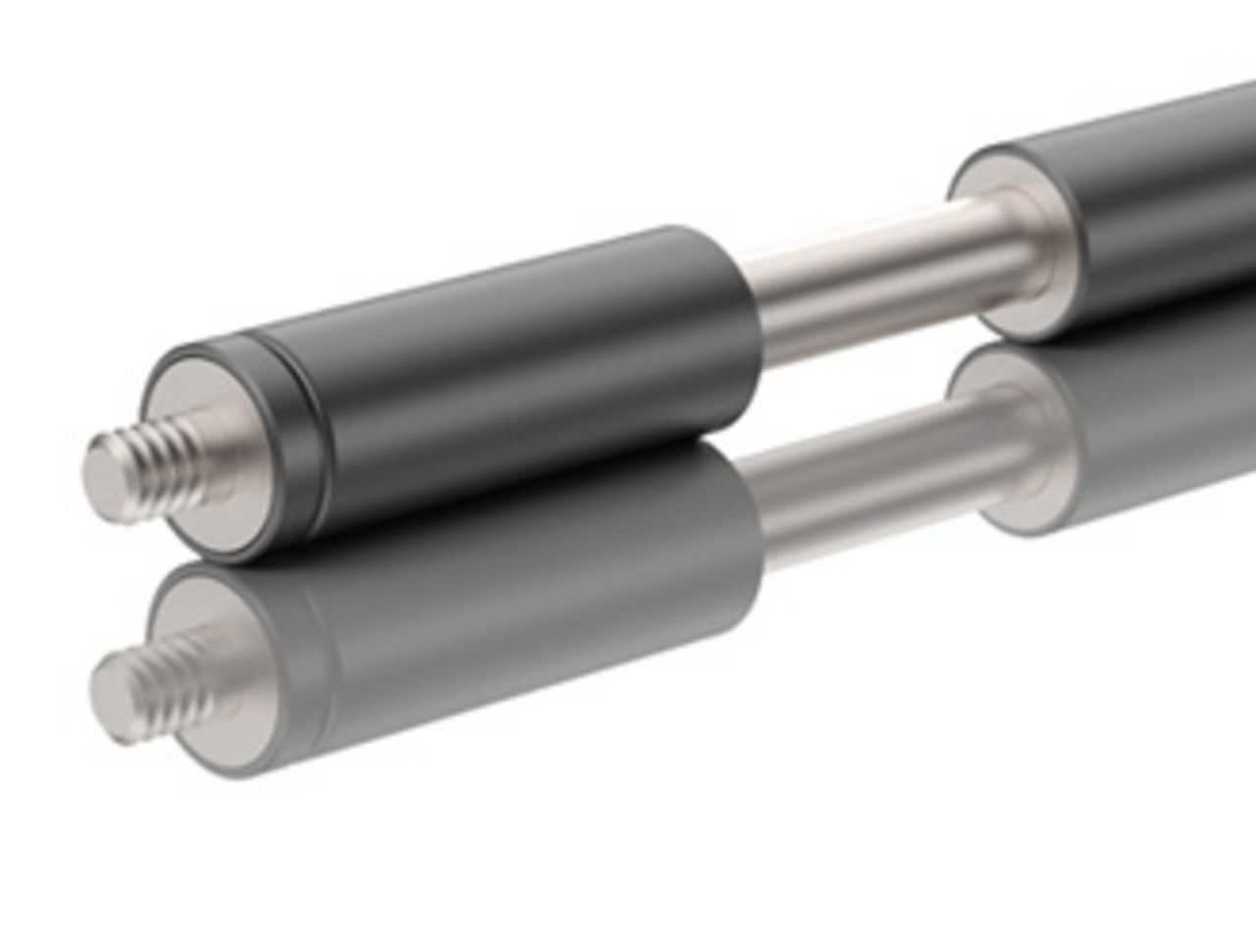

Spring-loaded locking gas springs

Spring-loaded locking gas springs lock with a certain degree of elasticity. The gas springs therefore offers a certain amount of resilience to absorb shocks or vibrations.

Product range

Gas pull spring

Gas tension springs are used to support or generate tensile forces, i.e. they act in the opposite direction to gas springs. In this way, the gas traction spring acts as an aid for opening movements,

e.g. of flaps or doors.

Product range

Double lift springs

The advantage of double lift springs is that they can work efficiently in both directions, both when compressing and extending. Double lift springs are often used in applications where tensile and compressive forces can occur.

Product range

Oil brakes

An oil brake uses a hydraulic system to generate and control braking force. A master cylinder generates the hydraulic pressure to achieve a controlled deceleration or stop.

Product range

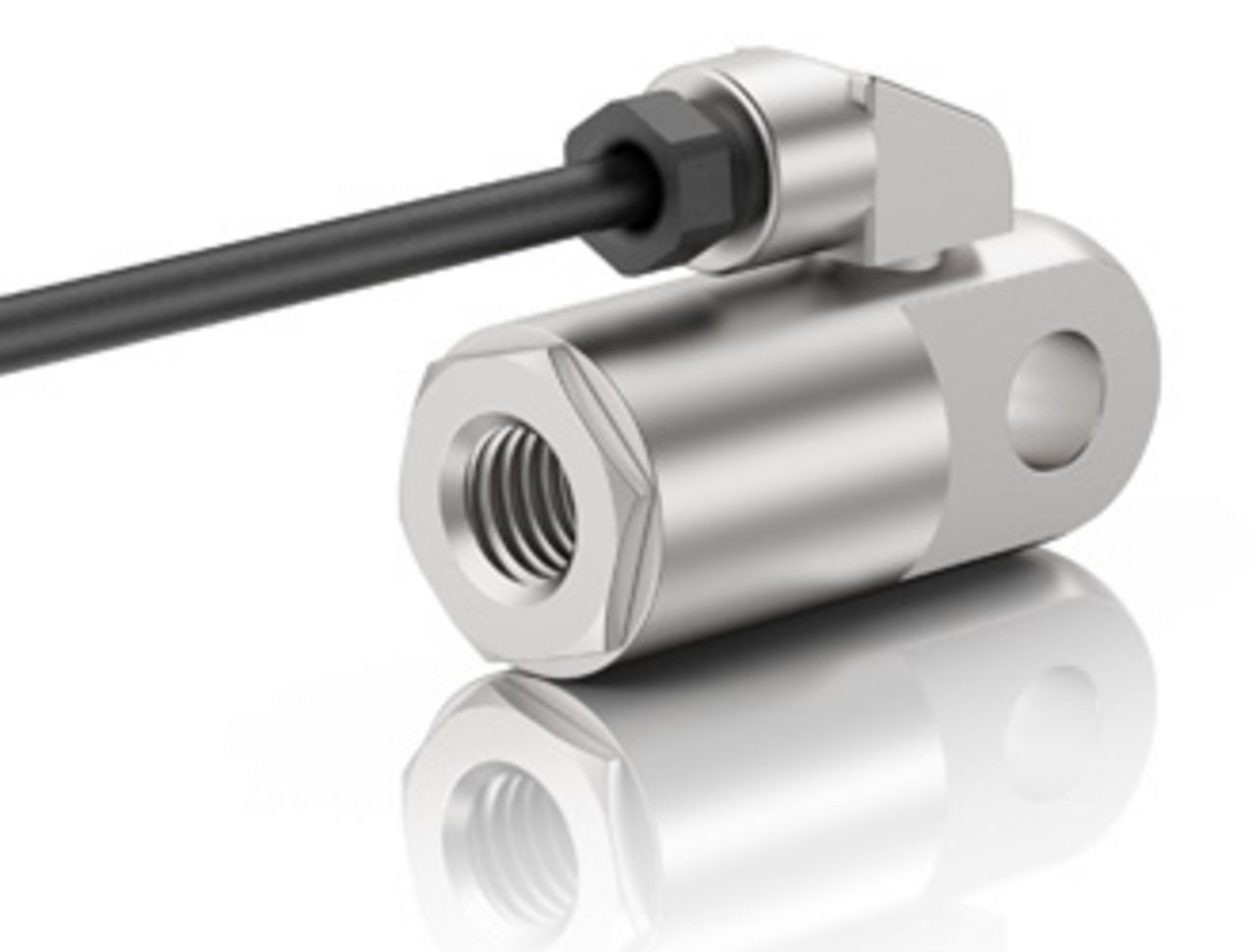

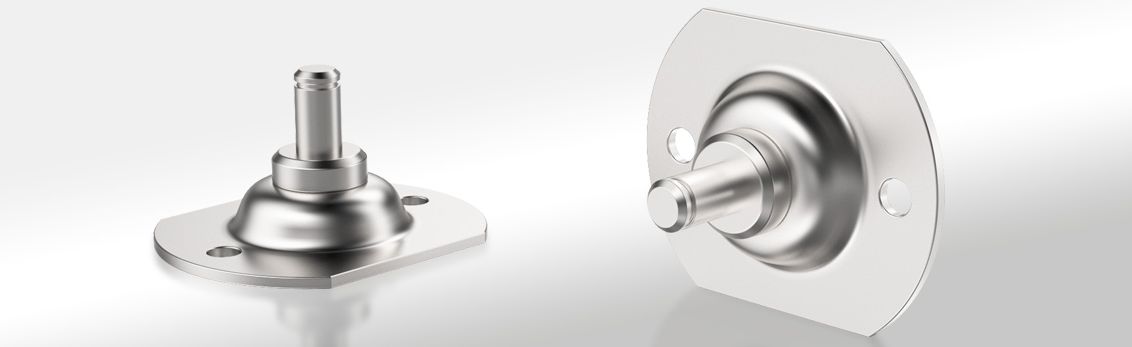

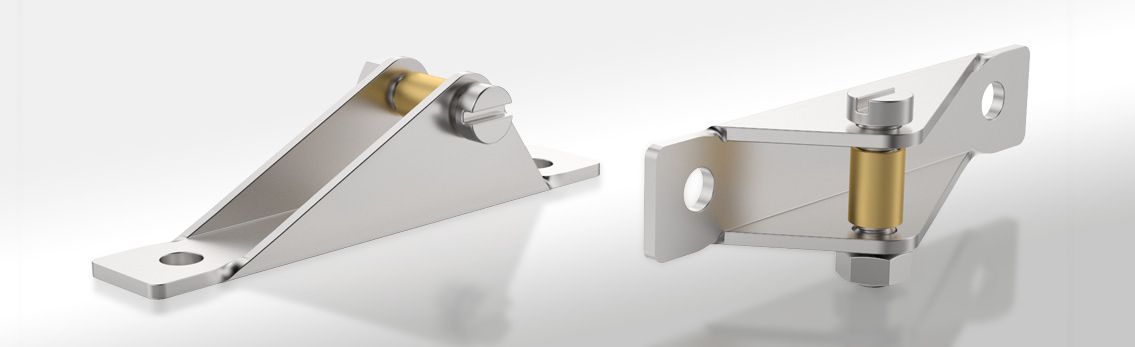

Fittings

Bearing shoes, side fittings, angle fittings, round fittings...

You will find the right socket with us.

Product range

Lever release

The lever release is required to release or lock lock lockable gas struts.

Product range

![[Translate to English:] Gasfedern, Gasfeder, Gasdruckfeder [Translate to English:] Gasfedern, Gasfeder, Gasdruckfeder](/fileadmin/_processed_/9/1/csm_gasdruckfeder_bauckhage_fc2e78795e.jpg)

![[Translate to English:] starr blockierende Gasfedern](/fileadmin/_processed_/7/1/csm_blockeribare_kl_824203fc99.jpg)

![[Translate to English:] Gaszugfedern](/fileadmin/_processed_/5/2/csm_gaszug_kl_3a484c8506.jpg)

![[Translate to English:] Stoßdämpfer, Gasfedern](/fileadmin/_processed_/1/5/csm_stossdaempfer_kl_fde54272ab.jpg)

![[Translate to English:] Beschläge für Gasfedern, Gasfeder, Gasdruckfeder](/fileadmin/_processed_/f/b/csm_contentbilder-beschlaege_de66d924d1.jpg)