Basically, a gas spring can be attached to the component in different ways. There are a few factors to consider in order to ensure safe and low-wear use. Once the correct gas spring has been selected depending on the tensile force and function, it is important to attach it correctly to the component The gas spring can be attached directly using a screw thread or by means of a fitting.

When choosing the right fitting, the required strength and stability play a decisive role. The Newton specification indicates this. This is therefore the first thing to consider when selecting the right combination of gas spring and fitting. It also depends on the nature of the component and the position in which the gas spring is to be fitted. How much space is available is also crucial and can be resolved based on the different fitting designs.

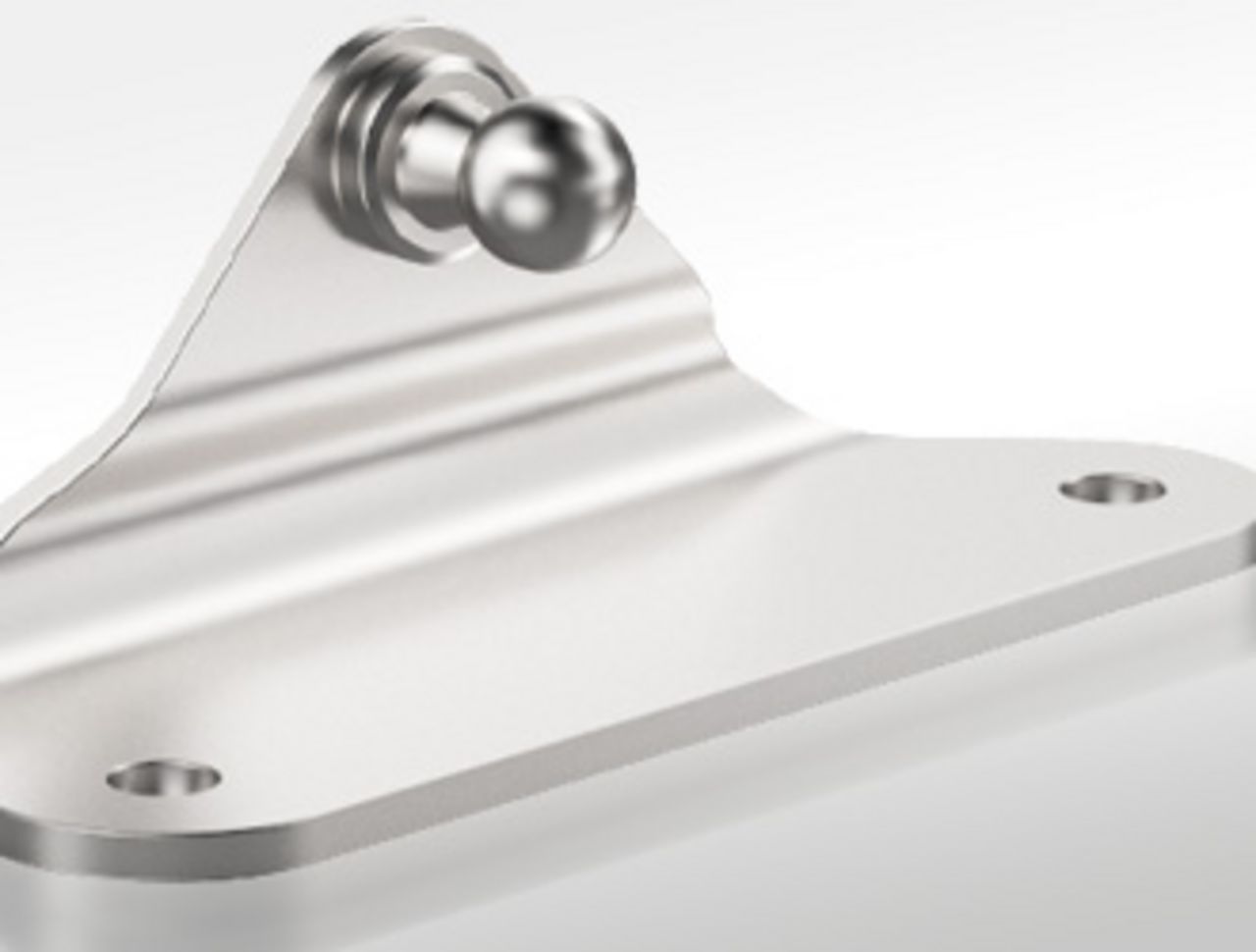

We offer four different fittings in our range. The bearing shoe is the fitting that offers the greatest stability. The connection of the gas spring is enclosed here by means of screw bolts. The guide is stable and secure. We offer bearing shoes in different sizes.

The side fitting is available as a pin or ball joint version. The difference lies in the guide direction, which offers a certain degree of flexibility with the ball joint. The side fitting is ideal for edge ends, for example, or where space is limited.

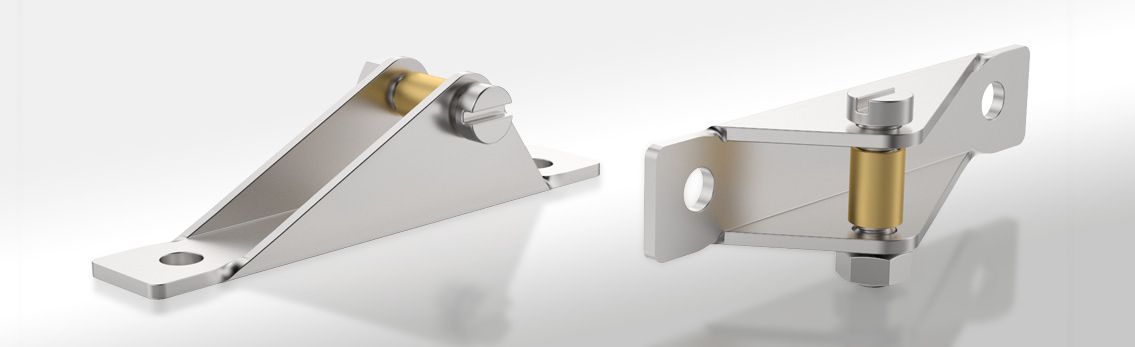

The angle fitting has a similar design. It has an L-shaped structure and allows the gas spring to be attached at right angles to the building element. Here too, there are versions with bolts or ball joints and different sizes.

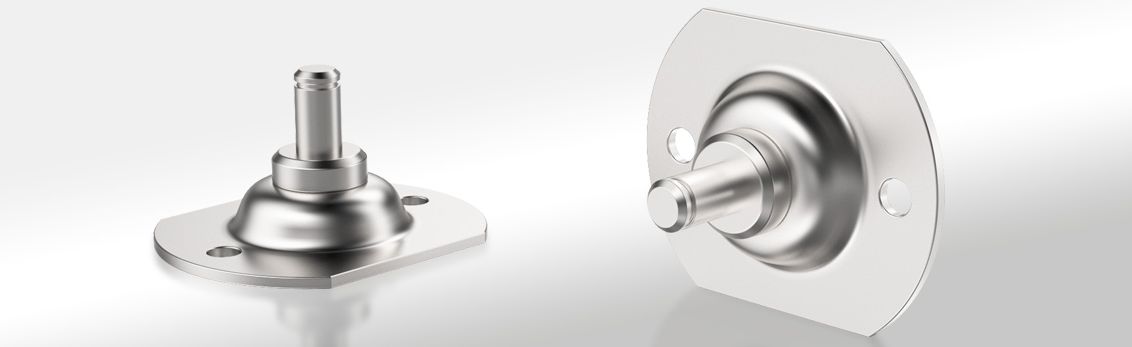

A round fitting offers a large contact surface and therefore high stability. If there are no restrictions in terms of space and position, the round fitting is a proven fastening for the gas strut.

Which fitting you need for your mounting therefore depends entirely on your requirements and the prevailing conditions. If you are unsure, we will be happy to advise you.